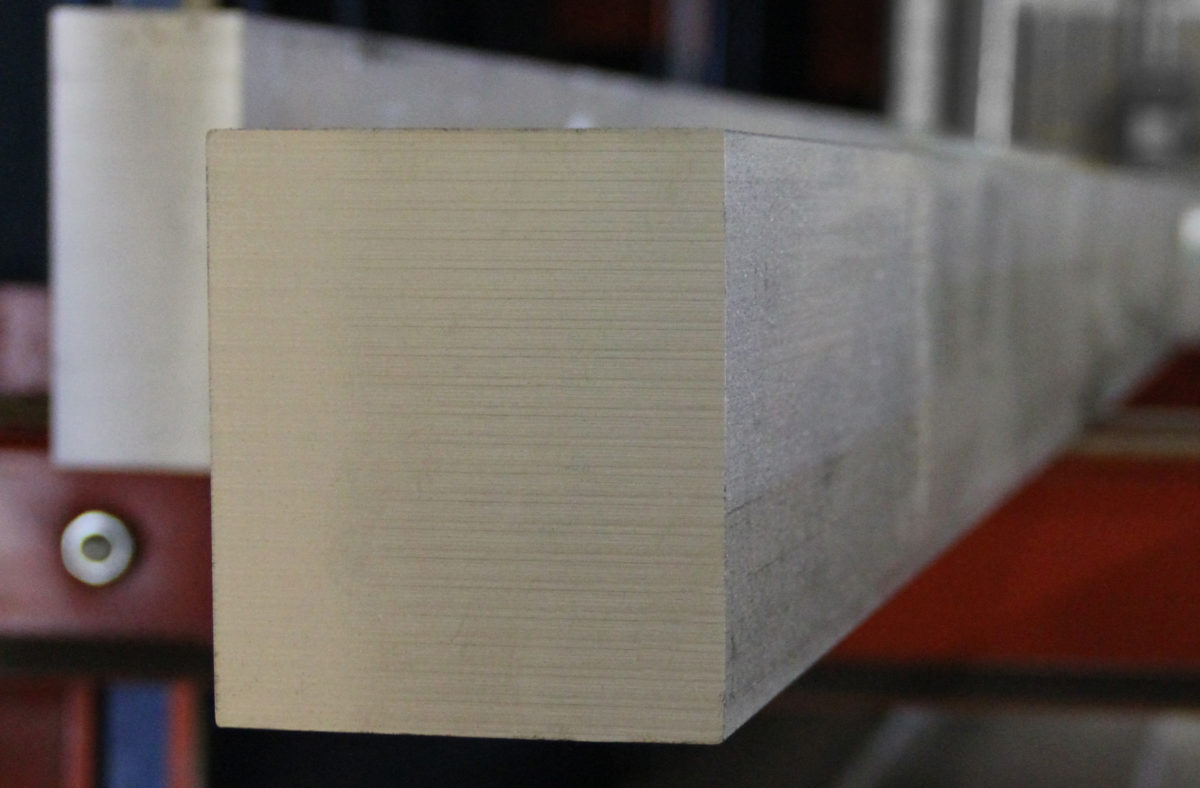

Extruded aluminum stock shapes, or extrusions, are inventoried by many aluminum extrusion distributors in 144” long master lengths. But did you know that you can quickly and easily order 6061-T6511 aluminum extrusions in custom lengths as short as 72” right off the press? It’s true! With as little as a 1,000# minimum and as quickly as a couple of weeks, custom length extruded aluminum bar stock can be available to ship from Howard Precision Metals to you. Because we are a 100% aluminum distributor, we know how to maximize our customers’ profits and minimizing scrap equals profits for you. With over 90 years of experience in the metals industry, we are considered by many to be the Premier Aluminum Distributor.

Why Should I Consider Purchasing Custom Lengths of 6061 Aluminum Bar?

There are many factors to consider when purchasing 6061-T6511 extruded aluminum bar stock. However, the most important variable is likely the end length of your parts. As stated before, custom length extruded aluminum bar stock can be purchased in lengths beginning at 72”. Maximum available lengths vary with each shape but can be as long at 300” or more! Let’s run through an example of how a custom length can save you big. Imagine you have an order for 108 pieces of 2” x 4” x 12.5” 6061 bar. With stock 144” aluminum rectangular bar lengths, you would yield only 11 pieces per bar. Not to mention, you would be left with an end drop of somewhere around 4” when you factor in the necessary saw kerf. Thus, you would require 10 bars to complete this job or roughly 1,255 pounds. If you purchased a custom length of 152.5” of this same aluminum rectangular bar, you would yield 12 pieces per bar. With the mill’s minimum purchase of only 1,000# on this aluminum rectangular bar stock, you would satisfy the minimum with an order of only 9 bars. The custom 152.5” lengths would cleanly yield the required 108 pieces for your job. Not only that, but you would only need to order 1,087 pounds of aluminum. That’s 168 lbs. less raw material than with 144” standard bars. Also, there would be no waste because there would be no end drop remaining with the custom length. This same thought process could be applied to a bar application with a final length of 78”. If you ordered 144” stock aluminum bars, you would end up with an awful lot of scrap. But, with a 2-3 week lead time and the minimum order quantity satisfied, you can order your aluminum bars produced to the 78” length. Think of how competitive your price to your customer would be if you eliminated ordering excess material and lessened your machine time.

How Ordering 6061 Extruded Aluminum Stock from Howard Precision Metals Saves You Time and Money

As previously stated, Howard Precision Metals is a 100% aluminum distributor. Because aluminum is all we do, we have picked up a few tricks along the way. Not only can our customers save by ordering custom length extrusions from us, but Howard Precision Metals has aluminum extrusion saws in house ready to cut your parts right to size. Because we are such a large volume aluminum extrusions distributor, we can get the fastest lead times on custom lengths from our mill sources. In fact, we consider the use of custom length aluminum extrusions with every production sawing order that we quote. Ordering the custom master lengths will minimize scrap and maximize yields, which will save you money in material. Anytime the volume and lead time allows, we offer this cost saving process to our customers. In addition to saving money on machine time, you also save on material. This type of double dipping discount is one of the many ways we offer the most competitive prices to our aluminum customers. We know that our customers must bid aggressively on every job and margins are tight. That’s why the aluminum experts at Howard Precision Metals offer creative solutions, such as custom lengths, to all our customers.

Ordering Custom Lengths Is a Lean Manufacturing Option

Just like our customers, we at Howard Precision Metals must consider ways to be more efficient in order to win orders. Because custom length aluminum extrusions minimize scrap, increase throughput, and lower overall costs, they are a truly lean manufacturing option. Just like our customers, we focus on ways to stay competitive. By trimming away excess and only ordering the aluminum that we need, we keep our prices attractive. Furthermore, we train all our sales professionals to look for creative, cost-saving solutions on every quote processed. Considering custom lengths of aluminum extrusions is likely the most commonly used solution that we offer our customers. Now, we are not going to give away all our secrets. But rest assured. With every quote processed, we offer the best process to save everyone time and money.

Order Your Custom Length Aluminum Extrusions Today

Though the blog is ending, your company’s custom length extrusion journey may be just beginning. Remember that minimums for custom lengths start at 1,000#, lengths are available at 72” and greater, lead times are as short as two weeks, and Howard Precision Metals processes cut to length extrusion orders with ease. Whether your next aluminum extrusion requirement is for one piece or a truckload, let us quote it for you. Contact us at 800-444-0311 or request a quote today.

Have you seen what we saw?